Driving Sustainability Forward

Powering the Circular Economy

Areion Diesel and the Circular Economy: Driving Sustainability Forward. As the world places greater emphasis on environmental protection and responsible resource management, industries like diesel remanufacturing play a critical role in the circular economy. At the heart of this model is the concept of reusing, recycling, and remanufacturing products to extend their lifespan and reduce waste—principles that align perfectly with Areion Diesel’s mission.

The U.S. Environmental Protection Agency (EPA) defines a circular economy as a

systems-focused approach that is restorative or regenerative by design. It aims to eliminate waste through thoughtful design and efficient resource use. This model reduces material consumption, redesigns products to be less resource-intensive, and transforms waste into valuable inputs for new manufacturing processes. Diesel engines are inherently built for longevity. With proper maintenance and multiple rebuilds, a single truck engine can last over a million miles, and construction equipment engines can perform reliably for thousands of hours. This long service life makes diesel engines ideal candidates for circular practices like remanufacturing.

How Areion Diesel Contributes to the Circular Economy:

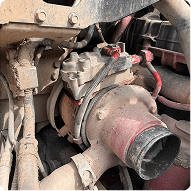

Engine Overhaul Begins

After approximately 200,000 miles, a diesel engine may require an overhaul. One critical component, the turbocharger core, is removed for evaluation.

Turbocharger Remanufacturing

The used turbocharger is sent to out to be rebuilt. Remove wording that says the used turbocharger is sent to Areion Diesel, where it is carefully disassembled, cleaned, and assessed. Reusable parts—such as the housing and core elements—are machined back to original equipment standards. Components beyond repair are replaced with high-quality Areion parts, such as gaskets, wheels, housing, and clamps.

Waste Minimization and Material Recovery

Any components that cannot be reused are recycled—often melted down to create raw materials for other manufacturing needs. This process diverts waste from landfills and reduces demand for new raw materials like iron ore and aluminum.

Reassembly and Reuse

The remanufactured turbocharger is reassembled, balanced for performance, and returned to the customer—delivering reliability at a fraction of the cost of a new part. Once installed on the overhauled engine, it’s ready for another 200,000-mile journey.

Reassembly and Reuse

The remanufactured turbocharger is reassembled, balanced for performance, and returned to the customer—delivering reliability at a fraction of the cost of a new part. Once installed on the overhauled engine, it’s ready for another 200,000-mile journey.

Waste Minimization and Material Recovery

Any components that cannot be reused are recycled—often melted down to create raw materials for other manufacturing needs. This process diverts waste from landfills and reduces demand for new raw materials like iron ore and aluminum.

The Value of Remanufacturing

Remanufacturing restores used components to like-new condition, preserving valuable materials and reducing the environmental impact of diesel engine maintenance. Areion Diesel’s components are built with the highest-quality materials and, with proper upkeep, can endure through several rebuild cycles. By supporting these sustainable practices, Areion Diesel helps power the future of transportation and heavy industry—responsibly.

Remanufacturing restores used components to like-new condition, preserving valuable materials and reducing the environmental impact of diesel engine maintenance. Areion Diesel’s components are built with the highest-quality materials and, with proper upkeep, can endure through several rebuild cycles. By supporting these sustainable practices, Areion Diesel helps power the future of transportation and heavy industry—responsibly.

We our a proud member of MEMA

Remanufacturing restores used components to like-new condition, preserving valuable materials and reducing the environmental impact of diesel engine maintenance. Areion Diesel’s components are built with the highest-quality materials and, with proper upkeep, can endure through several rebuild cycles. By supporting these sustainable practices, Areion Diesel helps power the future of transportation and heavy industry—responsibly.

A remanufactured turbocharger can reduce climate change potential by 52.2% & after 83.9% in energy savings.

Source: Analysis of the life cycle environmental Impact reductions of Remanufactured Turbochargers, * Journal of Remanufacturing, Springer (2022)